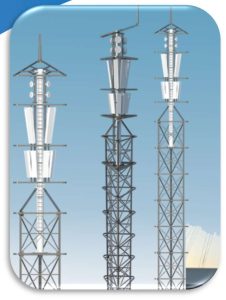

Pultruded FRP Solution for Camouflage Towers

Our focus extends to the production of camouflage towers utilizing Pultruded Fiber fiber-reinforced polymer (FRP) solutions. These towers are meticulously crafted to seamlessly integrate with their surroundings, offering a harmonious balance between aesthetic allure and operational functionality. Leveraging our proficiency in camouflage design and fabrication, we excel in developing towers that seamlessly blend into their natural environment, rendering them virtually indistinguishable. This specialized approach makes our camouflage towers an ideal choice for sensitive locales and urban environments, effectively concealing their presence while addressing both technical requirements and environmental considerations with precision and efficacy.

Modern techniques for manufacturing camouflage towers, specifically for telecommunications and observation purposes, involve a blend of advanced materials, design methodologies, and integration techniques. These towers are designed to seamlessly blend with their surroundings, whether urban or natural landscapes, to minimize visual impact while fulfilling their functional requirements. Here’s a detailed overview of the techniques and technologies involved.

Design and Planning: The initial stage involves detailed planning and design, where the location and purpose of the tower dictate its appearance. Design software like AutoCAD and other 3D modeling tools are utilized to simulate and visualize the tower’s aesthetics in its intended environment.

Material Selection: Modern camouflage towers are constructed using materials that mimic the physical appearance of their surroundings.

Common Materials Include

Fiberglass Reinforced Plastic

Lightweight and durable, FRP can be molded and textured to resemble various surfaces like tree bark, stone, or even architectural details of buildings.

Steel Structures

Used as the core frame, steel provides the necessary strength and is often shaped and treated to form part of the camouflage, such as branches or architectural elements.

High-Density Polyethylene

Used for its flexibility and durability in outdoor environments, H-D Polyethylene can be crafted to mimic leaves, grass, and other natural elements.

Manufacturing Techniques

Molding and Texturing: Advanced molding techniques are used to create complex shapes and textures that replicate natural and man-made objects. This might involve using detailed molds designed with the help of 3D printers.

Color Matching: Using UV-resistant paints and coatings that match the surrounding environment, manufacturers ensure that the tower remains inconspicuous throughout its lifecycle. Spectrophotometers and color-matching software help in achieving precise hues and shades.

Structural Fabrication: The steel framework is fabricated using precision cutting, welding, and bolting to ensure high structural integrity and ease of assembly on site.

Assembly and Installation: Camouflage components are often pre-assembled in modules to minimize on-site construction activity.

The installation process may involve:

Modular Construction: Prefabricated sections are transported to the site and assembled using cranes and other heavy machinery.

Integration with Existing Structures: In urban environments, parts of the camouflage might be integrated with existing buildings or infrastructure to maintain aesthetic continuity.

Landscape Integration: In rural or natural settings, additional landscaping may be done around the tower to enhance the camouflage effect.

Maintenance and Sustainability: Modern camouflage towers are designed with sustainability in mind. Materials used are often recyclable or have a low environmental impact. Maintenance involves regular inspections to ensure that the camouflage remains effective and the structural integrity is intact.

Technological Integration

At Alwasal, we understand that the integration of advanced technology is crucial for delivering superior construction solutions. Our commitment to technological innovation ensures that we stay at the forefront of the industry, providing our clients with efficient, reliable, and sustainable solutions. By embracing the latest advancements in construction technology, we enhance project accuracy, streamline processes, and improve overall project outcomes.

These towers are equipped with 360-degree state-of-the-art wireless and data transmission technology, ensuring they meet their primary functional requirements without interference, despite their camouflaged design.

Through the use of these advanced manufacturing techniques, modern camouflage towers are able to meet both aesthetic and functional needs, thereby minimizing their visual impact while maximizing their utility.